| • |

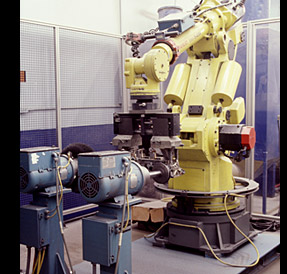

4 machining centers |

| • |

Consistent, reliable

block machining and cylinder boring |

| • |

Flexibility to

machine multiple engines and engine families |

| • |

Automatic offset,

in-machine workpiece measuring |

| • |

Higher spindle

speeds |

| • |

Turn boring accuracy

to +0.05 mm with over 1.33 C |

| • |

Precision liner

glass scales in X, Y and Z axes |

| • |

Consistently achieve

highest accuracy measurements |

| • |

Reduce cycle times

by 55% |

| • |

Provide same-day

entire engine assembly replacement |

| • |

Maintain well-stocked

inventory of engines |